TSH Technology

Breakthrough Technology for Induction Contour Hardening of Complex Geometry Parts

What is TSH Technology

- Synergistic combination of controlled low hardenability (LH) advanced steels and superior induction hardening techniques.

- TSH Technology serves the Automotive, Commercial Vehicle, Agriculture, Mining, Industrial and Railroad Industries as an alternative steel / heat treat technology for case hardening (carburizing, carbonitriding), through hardening and conventional induction hardening of heavy duty alloy steel parts

- TSH = Through Heating for Surface Hardening, Parts are through heated by low or medium frequency induction heating and then rapidly quenched resulting in a surface hardened layer profiling the part.

- Parallel axis gears

- Differential bevel gears

- Spiral bevel gears

- Track bushings

- Transmission shafts

- King pins, diff pins, piston pins, ball Joints

- Leaf and coil springs

- Journal and differential crosses

- Camshafts and crankshafts

- Tillage tools

- Grinding mill balls

- Bearings

TSH Benefits

1. Cost Effective Alternative Process

Uses low cost TSH steels

- 3-8 times less alloying elements (Mn, Cr, Ni, Mo)

- Expensive alloy elements (Ni, Cr) are not specified

Replaces carburizing or conventional induction hardening for many alloy steel parts

- TSH cycle times 1-5 minutes versus 8-20+hours for carburizing

Lean and green process allowing individual gear traceability

2. Superior Metallurgy / Improved Durability

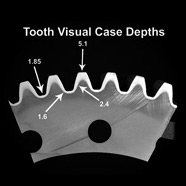

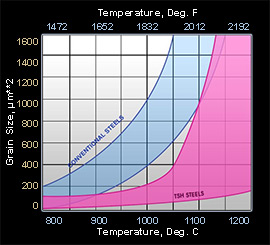

- Produces fine-grain to ultra-fine grain martensitic structures within the surface hardened layer

- Improves surface metallurgy by eliminating grain boundary oxidation or nonmartensitic surface layer Associated with gas carburizing

- Heat treated core structure (bainite and pearlite) resulting in a good combination of core ductility and strength.

- Develops high magnitude of the desirable compressive surface residual stresses (600-1000 MPa)

- Significantly improved static and dynamic properties

3. Simple, Repeatable and Robust Process

- Parts are through heated or partial heated and then rapidly quenched

- Hardened depth is controlled by the steel's hardenability

- Limited steel hardenability allows the formation of well defined hardness pattern when hardening complex-geometry parts

- Uses low or medium induction hardening frequencies (1kHz to 15kHz)

- Reduce equipment capital cost

- Dramatically reduces probability of overheating edges, tips and corners

- Improves overall repeatability and robustness. Reduces process sensitivity

TSH Case Studies

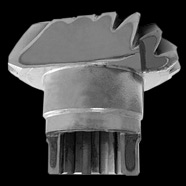

Case Study: Hypoid Drive Pinion – TSH Process vs Gas Carburized

The conventional heat treat process for hypoid drive pinion is gas carburizing. Conventional induction contour hardening is not practical due to the complex part geometry. The TSH technology makes induction contour hardening of this part possible.

| TSH Benefits |

TSH Processed |

Gas Carburized |

| Lover Cost Steel |

60LH |

8625H |

| Reduced Cycle Times |

3 minutes |

12 hours |

- Superior Metallurgy

- Finer Grain Size

- No Grain Boundary Oxidation

- No Nonmartensitic Surface Layer

|

- Fine grain martensite

- GS# 9-12

- None

- None

|

- Coarser grain high carbon plate martensite

- GS# 5-8

- 10-25 microns

- 10-25 microns

|

| Enhanced Compressive Residual Stresses |

High Compressive (600-1000 MPa) |

Low Compressive (140-300 MPa) |

| Improved Fatigue Life |

2-3X |

1 |

| Eliminates Shot Peening |

Not needed |

Needed |

| Environmentally Friendly |

Minimal Emissions, Energy Efficient, Water Quench |

Exhaust Gases, Energy Intensive, Oil Quench |

| Lean Process |

In line single part process |

Stand Alone, Batch Process |

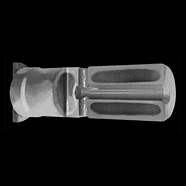

Case Study: Helical Bull Gear – Induction Hardened by TSH Process

Induction contour hardening technology can be used for this 13” helical bull gear to replace gas carburizing. TSH technology is the best contour hardening process for these larger parts. The TSH process utilizing lower power, low frequency induction heating reduces equipment cost and makes the process more repeatable and robust. In addition, the core of the gear tooth is heat treated.

Helical Bull Gear

- Outer Diameter = 330 mm (13”)

- Number of Teeth = 47

- Module = 6.8 mm

- Weight = 13.8 kg (29#)

Helical Gear Chemistry by Stork Climax Research Services

| C |

Si |

Mn |

Cr |

Ni |

Mo |

S |

Ti |

V |

| 0.79 |

0.08 |

0.06 |

0.17 |

0.06 |

<0.02 |

0.015 |

0.79 |

<0.008 |

Advanced TSH Steel Technology

Characterized by:

- low or no alloy content

- reduced tendency for grain growth during heating

- LH steels control harden depth capability

- capability to develop high compressive residual stresses

Typical LH Steel Chemistries

| Chem. Element |

Gears, Spiders, Springs |

Gears, Bearings |

| C |

0.55-0.630.62-0.67 |

0.77-0.83 |

| Si |

0.10-0.300.15 max |

0.10-0.25 |

| Mn |

0.20 max0.20 max |

0.10 max |

| Cr |

0.15 max0.10 max |

0.10 max |

| Ni |

0.25 max0.10 max |

0.10 max |

| Mo |

-- |

- |

| S |

0.04 max0.04 max |

0.04 max |

| P |

0.04 max0.035 max |

0.035 max |

| Ti |

-0.06-0.12 |

0.06-0.12 |

| V |

-<0.40 |

<0.40 |

Temperature Table

Meet the Steel Cost Challenge Utilizing TSH Steels

| Steel |

Mn |

Cr |

Ni |

Mo |

| TSH Steel |

≤0.20 |

≤0.15 |

≤0.25 |

- |

| 9310H |

0.40/0.70 |

1.0/1.45 |

2.95/3.55 |

0.08/0.15 |

| 4817H |

0.40/0.70 |

- |

3.2/3.8 |

0.20/0.30 |

| 4320H |

0.40/0.70 |

0.35/0.65 |

1.55/2.0 |

0.20/0.30 |

| 8822H |

0.70/1.05 |

0.35/0.65 |

0.35/0.75 |

0.30/0.40 |

| 8620H |

0.60/0.95 |

0.35/0.65 |

0.35/0.75 |

0.15/0.25 |

| 4118H |

0.60/1.0 |

0,30/0.70 |

- |

0.08/0.15 |

| 5120H |

0.60/1.0 |

0.60/1.0 |

- |

- |

Reduced Alloy => Lower Cost

Techmash America, Inc. Assumes

"Total Application Responsibility" for Your Parts

Part Selection and Evaluation

- Customer specifies part

- TSH feasibility and LH steel selection by Techmash America, Inc.

- Cost savings evaluated by Techmash America, Inc. and customer

Process Development for Prototype Parts

- Techmash America, Inc. supplies LH steel to customer

- Customer manufactures part from supplied LH steel

- Techmash America, Inc. together with Inductoheat inc develop the TSH process and heat treat prototype parts

Prototype part evaluation and testing

- Customer verifies quality of prototype parts

- Customer tests prototype parts

Part qualification for production

- Induction equipment supplied by Inductoheat, Inc

- Technical support provided by Techmash America, Inc. and Inductoheat, Inc

- LH steel produced by North American steel supplier developed by Techmash America, Inc.